Review Article, J Biochem Eng Bioprocess Technol Vol: 1 Issue: 2

A Review of Lignin Chemistry and its Biorefining Conversion Technologies

Rachita Rana1, Sonil Nanda2, Venkatesh Meda1, Ajay K Dalai1* and Janusz A Kozinski3

1Department of Chemical and Biological Engineering, University of Saskatchewan, Saskatoon, Saskatchewan, Canada

2Department of Chemical and Biochemical Engineering, University of Western Ontario, London, Ontario, Canada

3New Model in Technology and Engineering, Hereford, Herefordshire, United Kingdom

*Corresponding Author : Ajay K Dalai

Professor and Canada Research Chair, Department of Chemical and Biological Engineering, University of Saskatchewan, Canada

Tel: (306) 966-4771

Fax: (306) 966-4777

E-mail: ajay.dalai@usask.ca

Received: June 01, 2018 Accepted: July 26, 2018 Published: August 02, 2018

Citation: Rana R, Nanda S, Meda V, Dalai AK, Kozinski JA (2018) A Review of Lignin Chemistry and its Biorefining Conversion Technologies. J Biochem Eng Bioprocess Technol 1:2.

Abstract

Lignin is potentially an abundant source for the synthesis of energydense fuels, phenolic chemicals, high-performance polymers, carbon fibers and value-added products surrogate to those conventionally obtained from fossil fuels. Low in cost, abundant in existence and product efficiency equivalent to the petroleum-derived products make lignin an excellent naturally occurring feedstock. This review attempts to broadly present the recent advancements in the field of lignin conversion and its applications as an energy resource. The growing popularity of lignin and the comprehensive research that is being conducted on biorefining has led to the inception of compiling this valuable information in the form of a review presented herewith. This review encompasses the vast extensive research towards lignin conversion and the new developments in this field. This paper reviews the chemistry of lignocellulosic biomass and the physicochemical changes occurring during biomass pre-treatment. Several ligninolytic microorganisms responsible for the degradation of lignin are also discussed. In addition, pyrolysis, liquefaction, gasification and microwave treatment for lignin conversion to biofuels and chemicals are elaborated.

Keywords: Lignin; Biomass chemistry; Pyrolysis; Liquefaction; Gasification; Microwave treatment; Biofuels; Biochemicals

Introduction

The depleting fossil fuels have made it essential for the energy sector to bring the biomass-derived fuels to spotlight. The increasing energy demands and the current human lifestyle have made sustainability, renewability, commercial viability and environmental impact as the major focus of the global energy sector. The worldwide search for acceptable fuels has continued and still poses a major challenge to the scientific and technological advancements. The requirement is to produce a biofuel that has similar properties as the conventional fuel to have blends and substitution without affecting the existing motor engines. Biofuels such as bioethanol, biobutanol and biodiesel hold many promising outcomes in the transportation sector. The prominent concern when discussing these biofuels is their quantitative production to meet the large energy demands of the world [1].

Waste plant biomass or lignocellulosic biomass is a rich source of renewable organic matter that can be transformed to liquid or gaseous biofuels with the application of thermochemical or biochemical conversion technologies [2]. Since, lignocellulosic materials are nonedible plant residues their diversion towards biofuel production does not pose any risk to arable lands, food security or rise in food commodity prices [3]. Moreover, the biofuels produced from waste lignocellulosic biomass are carbon-neutral because they tend to decrease the net emissions of CO2 per unit of energy delivered upon combustion [4]. On the other hand, the CO2 resulting from the combustion of biofuels is utilized by the plants during photosynthesis.

Lignocellulosic biomass is not only inexpensive but also an abundant resource found globally that could sustain the production of biofuels [5,6]. It is estimated that the production of biomass from terrestrial plants at a global scale is 170-200 × 109 tons per annum, which has tremendous possibilities for biofuel production [7]. This vast amount of biomass supply could suggestively supplement a major portion of the worldwide energy consumption of 500 EJ/year [8]. Lignocellulosic biomass can be categorized into agricultural residues (e.g. straw, husk, stover, shells and bagasse), wood residues (e.g. softwood, hardwood and sawdust) and energy crops (e.g. Timothy grass, switch grass and hybrid poplar).

The term “lignocellulose” originates from “lignin” and “cellulose” which are the two primary components of plant cell wall. In addition to lignin and cellulose, plant cell walls comprise of hemicellulose and extractives as the organic compounds. The cellulose, hemicellulose and lignin form an intricate organic network that is supported by van der Waals forces, covalent bonds and intermolecular bridges. This complex chemistry of lignocellulosic biomass makes them recalcitrant to attack by enzymes, microorganisms, pests and insects [9].

The starch-based materials (food grains, corn, potato, sugarcane, cassava, etc.) are considered as the first-generation biofuel feed stocks owing to their traditional use for bioethanol production though fermentation without any intensive pre-treatment process. Since these first-generation feed stocks are food-based, they are often criticized for food vs. fuel crisis. In contrast, lignocellulosic biomasses are nonfood materials and second-generation biofuel feed stocks. Unlike first-generation starch-based feedstocks, lignocellulosic biomass requires physical, chemical and biological pre-treatments to recover fermentable sugars for conversion to biofuels. While the starchbased biomasses are targeted mostly toward bioethanol production through fungal or bacterial fermentation, lignocellulosic feed stocks can produce wide-ranging biofuel products such as bio-oil, biodiesel, bioethanol, biobutanol, biogas, syngas and hydrogen [10].

The advancements towards efficient lignocellulosic biomass conversion to quality fuel products rely on lignin and cellulose. Lignin follows cellulose in being the most abundant biopolymer naturally found on the earth. Lignin abundantly contains nature’s aromatic (phenolic) polymers, even more than any other naturally occurring substance [11]. In plants, lignin acts as a reinforcing material to the cellulosic fibers. It is reported that almost 60% excess lignin is generated than what is needed to meet the internal energy demands for its combustion to produce fuels and chemicals [12-17]. This justifies the need to develop processes that can make an efficient and economical use of lignin towards energy generation. Lignin being rich in aromatic contents and abundantly present as a renewable feedstock has driven attention to producing energy-dense second-generation biofuels. Although lignin appears to be an excellent biomaterial trapped in the plant biomass, its applications are just starting to be realized on different platforms.

The abundant existence of lignin as a potential ingredient of lignocellulosic biomass makes it essential for biofuel refineries and bio product industries to focus on the development of technologies to efficiently derive fuels, chemicals and value-added products. The literature on lignin is available marginally and is scattered. This work is an attempt to systematically present the structural chemistry, biosynthesis, as well as bio refining applications of lignin. This paper reviews several biochemical and thermochemical conversion technologies, as well as microwave treatment of lignin to fuels and chemicals.

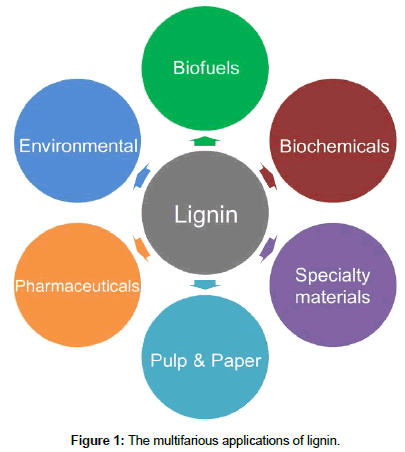

Applications of Lignin

In addition to fuel production, the diverse applications of lignin can be found in chemical production, specialty materials, pulp and paper industries, pharmaceuticals and environmental (Figure 1). Table 1 summarizes the various sub-disciplines under each of these industrial aspects for lignin application. Owing to its structural chemistry and easier recovery from lignocellulosic biomass, cellulose has gained the most spotlights in terms of the production of fuels, fine chemicals and engineered materials (fibers, tubes, aerogels, electronics, packaging, 3D printing, etc.) [18]. The use of lignin derivatives has found diverse applications ranging from fuel to biomaterials. Due to the versatile properties of lignin, various value-added industrial applications have been recognized. Lignin has proven to exhibit several health benefits such as anti-carcinogens, anti-inflammatories, prebiotics [19,20], antioxidants [21,22], antibiotics and antimicrobials [23-26].

| Industrial sector | Application |

|---|---|

| Biofuels | (i) Bio-oil from pyrolysis and liquefaction (ii) Syngas from gasification (iii) Green diesel via Fischer-Tropsch process (iv) Heat energy from combustion |

| Chemicals | (i) Phenolic compounds (ii) Dispersants (iii) Flocculants (iv) Paints (v) Adhesives |

| Specialty materials | (i) Biocomposites (ii) Bioplastics (iii) Carbon fibers (iv) Activated carbon (v) Adsorbent (vi) Board binder (vii) Foams (viii) Densification of biomass pellets (ix) Battery components (x) Energy storage |

| Pulp and paper | (i) Sizing agent (ii) Packaging and lamination (iii) High tensile strength |

| Pharmaceutical | (i) Antioxidants (ii) Antimicrobial agents (iii) Cosmetics (iv) Prebiotics |

| Environmental | (i) Dust controlling agent (ii) Soil stabilization (iii) Pesticide (iv) Herbicide (v) Water retention agent (vi) Heavy metal adsorption |

Table 1: Utility of lignin as a value-added product [13-17].

In novel materials engineering, lignin has been extensively used in the fabrication of polymeric materials for multifarious utility [27-29], biofuels [30-33], carbon fibres [34,35], graphene nanosheets [36], activated carbon [37,38], agriculture and construction [14]. Renewable gasoline has also been produced from lignin as the feedstock [32]. The by-products from lignin are also worthy of applications in a variety of industrially used goods. The wood lignin has been explored for biomaterial synthesis, but the use of herbaceous lignin has not been studied much. Li and Ragauskas [39] used different weight compositions of sucrose polyol and glycerol polyol to synthesize lignin-based polyurethanes. The coupling of bioengineering with biomass refining and pretreatment techniques is expected to contribute towards the synthesis of low-cost biopolymers, fungible green fuels, valuable chemicals, elastomers, carbon fibers and engineered plastics.

Lignocellulosic Biochemistry

Lignocellulosic biomass exemplifies a widely available and largely under-explored category of raw materials for the generation of biofuels such as bio-oil, bioethanol, biobutanol and hydrogen. The sugar (e.g. pentose and hexose) composition in the biomass decides the theoretical yield of alcohol fuels through fermentation. In contrast to woody biomass, agricultural residues demonstrate a higher surface area and smaller pore volume, which reduces their susceptibility to enzymatic hydrolysis and other pretreatments [40]. Furthermore, hardwood biomass has more cellulose than hemicellulose resulting in higher glucose yields compared to and xylose for easier bioconversion [41]. Lignocellulosic biomasses are composed of 35-55 wt% cellulose, 20-40 wt% hemicellulose and 10-25 wt% lignin in addition to extractives (e.g. pectin, resins, waxes, etc.), ash and minerals [42-47]. The composition of cellulose, hemicellulose, lignin and extractives in a few lignocellulosic biomasses are shown in Table 2.

| Biomass | Cellulose | Hemicellulose | Lignin | Extractives | Reference |

|---|---|---|---|---|---|

| Almond shell | 50.7 | 28.9 | 20.4 | 2.5 | [43] |

| Apricot stone | 22.4 | 20.8 | 51.4 | 5.2 | [44] |

| Bagasse | 41.3 | 22.6 | 18.3 | 13.7 | [45] |

| Bamboo | 42.4 | 27.9 | 23.1 | 4.4 | [46] |

| Barley straw | 42.0 | 21.9 | 19.4 | 6.8 | [47] |

| Cashewnut shell | 36.2 | 16.4 | 18.3 | 8.4 | [45] |

| Coconut coir | 47.7 | 25.9 | 17.8 | 6.8 | [45] |

| Coconut shell | 36.3 | 25.1 | 28.7 | 8.3 | [45] |

| Coir pith | 28.6 | 15.3 | 31.2 | 15.8 | [45] |

| Corn cob | 45.0 | 35.0 | 15.0 | 15.4 | [45] |

| Corn stalk | 42.7 | 23.6 | 17.5 | 9.8 | [45] |

| Eucalyptus wood | 48.0 | 14.0 | 29.0 | 2.0 | [48] |

| Flax straw | 28.7 | 26.8 | 22.5 | 19.5 | [49] |

| Groundnut shell | 35.7 | 18.7 | 30.2 | 10.3 | [45] |

| Hazelnut shell | 25.2 | 28.2 | 42.1 | 3.1 | [50] |

| Legume straw | 28.1 | 34.1 | 34.0 | 2.0 | [44] |

| Millet husk | 33.3 | 26.9 | 14.0 | 10.8 | [45] |

| Oat straw | 39.6 | 22.4 | 18.2 | 10.1 | [47] |

| Olive husk | 24.0 | 23.6 | 48.4 | 9.4 | [43] |

| Pine cone | 32.7 | 37.6 | 24.9 | 4.8 | [51] |

| Pinewood | 38.8 | 23.6 | 20.4 | 15.7 | [42] |

| Rice husk | 31.3 | 24.3 | 14.3 | 8.4 | [45] |

| Spurce wood | 43.0 | 29.4 | 27.6 | 1.7 | [50] |

| Sunflower shell | 48.4 | 34.6 | 17.0 | 2.7 | [43] |

| Tobacco stalk | 21.3 | 32.9 | 30.2 | 5.8 | [44] |

| Timothy grass | 34.2 | 30.1 | 18.1 | 16.5 | [42] |

| Walnut shell | 25.6 | 28.9 | 52.3 | 2.8 | [43] |

| Water hyacinth | 18.2 | 48.7 | 3.5 | 13.3 | [52] |

| Wheat straw | 39.1 | 24.1 | 16.3 | 19.2 | [42] |

Table 2: Composition of cellulose, hemicellulose and lignin in some lignocellulosic biomasses.

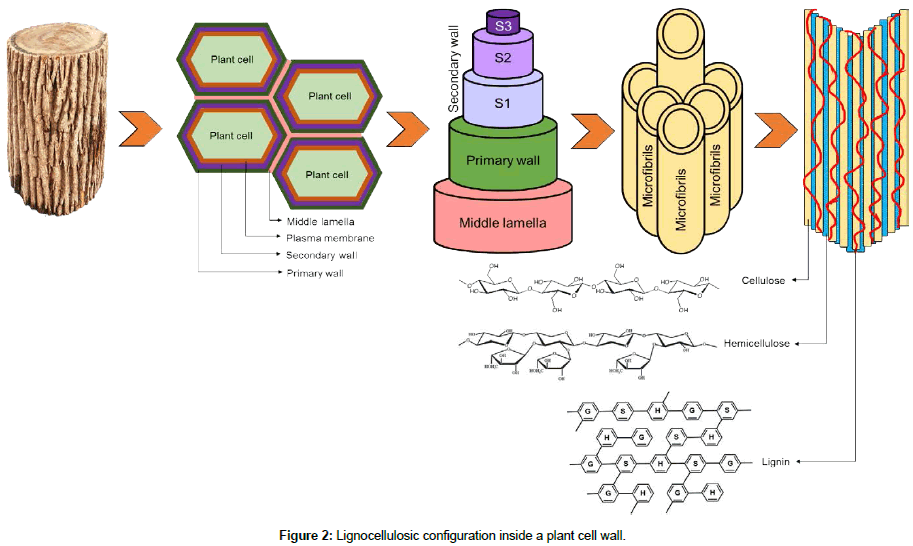

Figure 2 graphically illustrates the arrangement of cellulose, hemicellulose and lignin inside a plant cell. The plant cells consist of cell wall (primary wall and secondary wall), plasma membrane, cytoplasm and cell organelles (e.g. plamodesmata, chloroplast, thylakoids, vacuoles, mitochondria, vesicles, endoplasmic reticulum, ribosomes, Golgi apparatus, ribosomes, nucleus, leucoplast, etc.). The protoplast secretes the cell walls that act as structural support, integrity and protection to the cells. The plant cell wall consists of three layers such as primary wall, secondary wall and middle lamella [48-52]. The primary layer is relatively thin, flexible and provides protection to the cells as it is exposed to the external environment. In contrast, the secondary layer has three sub-layers termed as S1, S2 and S3 that contain lignin which further strengthens the call wall and makes it rigid and relatively waterproof (as lignin is waterinsoluble). The middle lamella, which contains pectins acts as a glue to hold all the adjacent cells together in an interface. The primary cell wall contains cellulose microfibrils produced by cellulose synthetase complex connected by hydrogen bonding for rendering tensile strength to the plant cells. Cellulose and hemicellulose are held together by polymeric lignin.

Cellulose (C6H10O5)n is a polysaccharide comprising of numerous β (1, 4) linked D-glucose units, which are aggregated through hydrogen bonding and van der Waals forces [53]. Cellulose is present in both crystalline and amorphous forms in lignocellulosic biomass. Moreover, cellulose has six crystalline forms, especially cellulose I, cellulose II, cellulose III1, cellulose III2, cellulose IV1 and cellulose IV2, among which cellulose I and II are largely found in lignocellulosic biomasses [54]. Cellulose I is the most common crystalline form of cellulose characterized by parallel glucan chains and strong intramolecular hydrogen bonding [55]. In addition, cellulose I has two crystalline polymorphs, namely cellulose Iα and cellulose Iβ. Cellulose Iα, predominant in lower plants and herbs, is metastable and triclinic, whereas cellulose Iβ, present in higher plants and woods, is monoclinic and stable [56]. Compared to amorphous cellulose that is easily hydrolyzable, the higher degree of crystallinity in crystalline cellulose leads to its requirement of intensive pretreatments such as those involving dilute acid, alkaline and cellulolytic enzymes [9,57].

Hemicellulose is a mixture of polysaccharides composed of pentose (C5) and hexose (C6) sugars such as arabinose, glucose, mannose, rhamnose and xylose. Hemicellulose also includes arabinoxylan, glucomannan, glucuronoxylan, xylan, xyloglucan, glucuronic acid and galacturonic acid. Cellulose is a long-chain polysaccharide made up of 7000-15000 units of glucose monomers, whereas hemicellulose is relatively short-chained consisting of 500- 3000 sugar monomers with acidic groups [58]. Cellulose has a higher degree of polymerization between 1,510 and 5,500, which strengthens is crystallinity [59]. On the contrary, hemicellulose has a lower degree of polymerization between 50 and 200, which makes it amorphous, easily hydrolyzable and hydrophilic [48]. Moreover, cellulose (342.3 g/mol) has a higher molecular weight than hemicellulose (150.1 g/mol for xylose). Cellulose (260°C-270°C) also has a higher melting point than hemicellulose ( ~ 145°C for xylose). The thermal devolatilization temperatures for cellulose and hemicellulose are 250°C-350°C and 200°C-300°C, respectively. However, lignin degrades at a much wider temperature range of 200°C-500°C [60].

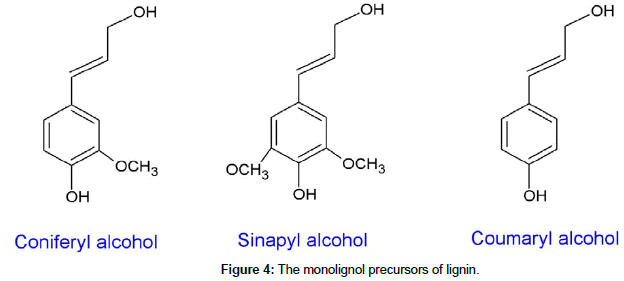

Lignin is a phenylpropane polymer comprising of p-coumaryl, coniferyl and sinapyl alcohols linked by ester bonds. Lignin tightly binds cellulose and hemicellulose together in a complex network through robust inter-chain covalent hydrogen bonding, thereby providing a higher-order structure and recalcitrance to plant cells [55]. Extractives are also present in lignocellulosic biomass in traces, which mostly includes chlorophyll, fatty acids, lipids, pectin, polar waxes, resins, tannins, terpenoids and sterols [49]. Alkali and alkaline earth metals, minerals, phosphorous, as well as some essential inorganic elements are also present in the biomass to conduct water and metabolites throughout the plant body and lifecycle [61].

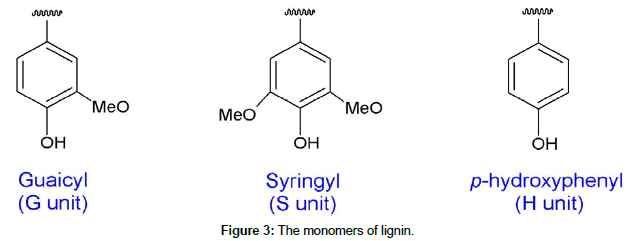

The polymeric chemistry of lignin makes it challenging to recover the sugars from cellulose and hemicellulose, which makes it indispensable for the biomass to undergo a hydrolytic pretreatment before bioconversion. Lignin is a naturally occurring amorphous, cross-linked and three-dimensional polymer that consists of guaiacyl (G), syringyl (S), and p-hydroxyphenyl (H) (phenylpropane) monomeric units (Figure 3). The precursors of the three phenylpropane units that produce lignin by the enzymatic dehydrogenative polymerization consist of three aromatic alcohols or monolignols such as coniferyl alcohol, sinapyl alcohol and p-coumaryl alcohol (Figure 4). Softwood lignin exclusively comprises of guaiacyl units along with small amounts of p-hydroxyphenyl units. In contrast, hardwood lignin is primarily composed of guaiacyl and syringyl lignin units along with small quantities of p-hydroxyphenyl units. Furthermore, lignin extracted from grasses and agricultural wastes consists of all three lignin units (i.e. G, S and H) and p-hydroxycinnamic acids, namely p-coumaric acid, ferulic acid and sinapic acid [62].

The heating value of lignin is typically in the range of 23.3-25.6 MJ/ kg, which is nearly 30% greater than that of holocellulose (i.e. cellulose and hemicellulose together) [63]. Holocellulose is made up of sugar units, which have a high degree of oxidation in contrast to lignin [43]. Therefore, holocellulose tends to have a lower calorific value and energy density than lignin. Lignocellulosic materials can essentially contain as high as 10-30 wt% of lignin and in some exceptional cases, the content can go as high as ~ 45 wt% [64]. The ash content of lignin can be as high as 15 wt%, which is due to the presence alkali metals such as sodium, calcium, potassium, magnesium, phosphorous and a few others as mentioned earlier. These inorganic impurities can be removed by washing lignin with sulfuric acid and hydrochloric acid [65,66].

Biomass Pretreatment

Chemically, lignin is hydrophobic and is found to be covalently linked to the structures of hemicellulose. It acts like cement filling in the voids that exist in the cell wall as a cross link between hemicellulose and cellulose [55,67]. This distinct cellular structure imparts mechanical strength to the plant and avoids collapsing of the water-conducting elements in plant cells. Lignin also functions as the barrier for carbohydrate fraction of lignocellulose to get access to enzymes. Therefore, highly lignified plants (e.g. higher plant and evergreen trees) are resistant to attack by insects, pests and parasites. The mechanisms that outline the protective action of lignin to prevent hydrolysis of enzymes are still not completely understood. The enzymes tend to bind to the structure of lignin and this causes a loss in the activity of these bonded enzymes due to their hydrophobic interactions with lignin [68].

Compared to starchy biomass, lignocellulosic feedstocks are relatively more recalcitrant. The factors contributing to the recalcitrance of lignocellulosic biomasses include (i) degree of lignification and polymerization, (ii) crystallinity of cellulose, (iii) specific surface area of cellulose, (iv) content of acetylated hemicelluloses, and (v) biomass pore volume [69]. The presence of lignin is a barrier against saccharification of lignocellulosic materials to release fermentable sugars from cellulose and hemicellulose for biofuel production. Therefore, it is desirable to denature and remove the polymeric lignin from the biomass to ease the access of chemicals and enzymes to cellulose and hemicellulose for hydrolysis.

Several physical, chemical and biological pretreatments are required for the breakdown the intricate polymeric framework in lignocellulosic biomass and release the monomeric sugars for fermentation to alcohols. A few pretreatments studied for lignocellulosic biomass include dilute acid, alkaline, ammonia fiber explosion, steam explosion, organic solvents, ozonolysis, pulse electrical field, ionic liquids, supercritical fluids and hydrolytic enzymes (e.g. cellulase, xylanase and β-glucosidase) [2,9,70]. An effective bioconversion of lignocellulosic biomass to alcohols requires a series of steps, which includes: (i) delignification of biomass to degrade the lignin network for releasing cellulose and hemicellulose, (ii) depolymerization of the polysaccharide to liberate sugar monomers, and (iii) fermentation of monomeric sugars monomers to alcohols.

Dilute sulfuric acid is the most widely used pretreatment agent for lignocellulosic biomass such as Bermuda grass [71], reed canary grass [72], silver grass, switch grass [73], Timothy grass [74], corn stover [75], corn fiber [76], rice straw [77,78], wheat straw [74,79], pinewood [74,80] and sugarcane bagasse [81,82]. Owing to the hydrophobicity, reticulation and three-dimensional polymerization, lignin is usually insoluble in hot water, acids and solvents. As lignin is resistant to organic solvents and acids, the dilute acid pretreatments have less impact on lignin removal [83]. The fraction of acid-soluble lignin is only up to 0.5 wt% in softwood and 5 wt% in hardwood [84]. However, alkaline treatments involving NaOH [54], NaCl [85] and acidified NaClO2 [55,86] are found to be efficient in the removal of lignin from the biomass. The degradation of lignin in alkaline solution results due to: (i) alkali-mediated cleavage of the ferulic acid cross-link between lignin and hemicelluloses, and (ii) alteration in polyelectrolyte properties of lignin induced by free carboxy1 groups of phenolic acids ethers [87].

Although delignification helps in lignin removal and acid pretreatment releases hemicellulose and amorphous cellulose, the hydrolysates often result in the generation of some chemical byproducts that are inhibitory to microbial growth and fermentation. Some of such inhibitors include furfural, hydroxymethylfurfural, acetic acid, ferulic acid, glucuronic acid, coumaric acid and phenolic compounds [88]. Hence, for a sustainable alcoholic fermentation, it is crucial to remove these inhibitors from the biomass hydrolysate. Qureshi et al. [89,90] suggested that over-liming the acidic hydrolysates could help in reducing the toxicity imparted by inhibitors. Over-liming involves raising the pH of the hydrolysate to 10 with the addition of Ca(OH)2 and 1 g/L Na2SO4 followed by boiling it to 90°C for 30 min and neutralizing the final pH to 7 with H2SO4.

Biological Conversion of Lignin

Biological conversion of lignin has diverse impacts on the quality of the soil. The conversion of plant debris with the help of microorganisms leads to the formation of humus through lignolysis that releases aromatic contents of humus from the residues to the soil. These ingredients primarily include degenerated lignin, terpenes, flavonoids, lignans and condensed tannins [91-93]. The major factors that inhibit the natural decomposition of highly lignified (lignin-rich) biomass could diversify depending on the geographic and climatic factors such as humidity, pH, oxygen, etc. High humidity, warm temperatures, high oxygen content and readily available biomass are favorable for microbial action in biological degradation of lignin. Moisture level exceeding the Fiber Saturation Point of biomass promotes fungal colonization and activity.

Highly lignified biomass needs specific microorganisms to convert them to useful products. Although lignin repels the conversion by most microorganisms, its microbial denaturation is majorly dependent on fungi such as basidiomycetes, white-rot fungi and brown-rot fungi. Lignicolous fungi are a group of fungi that have the capability to cause the decay or rotting of wood by permeating the fibrous structures into the wood fibers. This often results in an increased mass of the microbial cell along with high ligninolytic enzyme formation. The lignin-degrading enzymes generated by white-rot fungi include lignin peroxidase, manganese-dependent peroxidase, versatile peroxidase and laccase. Several accessory enzymes that enhance the biological lignin degradation include glyoxal oxidase, aryl alcohol oxidase, pyranose 2-oxidase, cellobiose/ quinone oxidoreductase and cellobiose dehydrogenase [94]. Table 3 summarizes a few significant fungal species and their enzymes responsible for lignin degradation.

| Fungus | Fungus group and type | Hydrolytic enzymes |

|---|---|---|

| Aspergillus niger | Ascomycota (Brown-rot) | Xylanases, Cellulases |

| Bjerkandera adusta | Basidiomycota (White-rot) | Lignin peroxidase, Manganese peroxidase |

| Clonostachys rosea | Ascomycota (White-rot) | Endopolygalacturonases, Galactosidase Endo-xylanase, Cellulases, Arabinofuranosidase, Acetylesterase, Xylosidase, Galactosidase |

| Fomitopsis palustris | Basidiomycota (Brown-rot) | Cellulases (Exo-glucanases, Endo-glucanases, β-Glucosidase) |

| Fusarium merismoides | Ascomycota (Brown-rot) | Endo-xylanase, Cellulases, Arabinofuranosidase, Acetylesterase, Xylosidase |

| Fusarium oxysporum | Ascomycota (Brown-rot) | Endopolygalacturonases galactosidase |

| Penicillium sp. | Ascomycota (White-rot) | Endo-xylanase, Cellulases, Arabinofuranosidase, Acetylesterase, Xylosidase |

| Phanerochaete chrysosporium | Basidiomycota (White-rot) | Lignin peroxidase, Manganese peroxidase |

| Pleurotus ostreatus | Basidiomycota (White-rot) | Xylanases, Cellulases, Laccase, MnP |

| Pleurotus pulmonarius | Basidiomycota (White-rot) | Endoglucanase, Cellobiohydrolase, Laccase, Manganese peroxidase |

| Pycnoporus cinnabarinus | Basidiomycota (White-rot) | Laccase, Lignin peroxidase, Manganese peroxidase |

| Strobilurus ohshimae | Basidiomycota (White-rot) | Lignin peroxidase, Manganese peroxidase |

| Trametes versicolor | Basidiomycota (white-rot) | Laccase |

Table 3: A few notable ligninolytic fungi and related enzymes [5].

A few white-rot fungi that are able to degrade lignin-rich biomass include Ceriporiopsis subvermispora, Heterobasidion annosum, Irpex lacteus, Phellinus pini, Phlebia spp., Pleurotus spp. and Trametes versicolor [94]. White-rot fungi are more effective on deciduous woods (angiosperms), whereas brown-rot fungi grow primarily on conifers woods (gymnosperms). The rotting activity by white-rot fungi is characterized by pale color due to oxidative bleaching and removal of lignin retaining a fibrous texture of crude polysaccharides. In contrast, the degradation by brown-rot fungi is characterized by brown color due to primarily degradation of wood carbohydrates and residual oxidized lignin. Some notable brown-rot fungi include Gloeophyllum trabeum, Laetiporus portentosus, Piptoporus betulinus, Postia placenta, Rhodofomitopsis lilacinogilva and Serpula lacrymans [94]. The white-rot fungi utilize a group of extracellular oxidative enzymes that can degrade lignin by penetrating its branched polymers, which include lignin peroxidases, manganese peroxidases, versatile peroxidases and dye-decolorizing peroxidases. The depolymerization is triggered by radical chemistry as these oxidative peroxidases contain heme co-factor.

Fungi can efficiently convert lignocellulosic biomass owing to their high enzymatic activity when compared to bacterial counterparts. The two types of enzymatic systems that are present in fungi are hydrolytic system and extracellular ligninolytic system. The hydrolytic system helps in the production of hydrolases (responsible for the conversion and degradation of polysaccharide), whereas the extracellular ligninolytic system functions towards degrading lignin and opening the phenyl rings. The research on enzymatic conversion of lignin is gaining attention over the past few years. The fungal enzymes that have been used for bioconversion of lignin are mostly lignin peroxidase, alkyl aryl etherase, manganese peroxidase and laccase. The two prominent enzymes expressed extracellularly by white-rot fungi are peroxidases and laccase. Mostly, during bioconversion, microorganisms show preferences towards lignin in the lignocellulosic degradation. It is found that most of these enzymes do not work independently towards lignin bioconversion but their respective content is the crucial factor for lignin conversion. There have been investigations towards the use of a soluble polymeric substrate that was derived from milled-wood lignin to see its applicability in the next-generation lignin-depolymerization.

Certain bacteria can also anaerobically digest the aromatics in lignin following the β-ketoadipate pathway [95]. When compared with fungi, bacteria do not retain the regular peroxidases for lignin degradation. This is because of the genetic limitations in the bacterial metabolic pathways that restrict the expression of these composite proteins that are glycosylated and contain disulfide bonds including calcium ions and a heme co-factor [96]. Although some bacterial lignin-degrading enzymes such as dye-decolorizing peroxidases have been discovered, they have lower lignin-oxidizing ability than fungi. Bacteria such as Acinetobacter baylyi [97,98], Nocardia [99], Rhodococcus opacus [100] and Streptomyces coelicolor [101,102] have gained popularity over other traditionally used strains due to their high lignin to lipid conversion along with properties of high lipid accumulation as well as excellent cloning mechanism [98,103]. The bacterial strains belonging to actinomycetes group are categorized as oleaginous species that have characteristic lipid accumulation of over 20%.

Kosa and Ragauskas [104] have studied the conversion to lignin model compounds to triacylglycerols (neutral lipids) using Rhodococcus opacus DSM 1069 and PD630 strains and nitrogen as the limiting parameter. The lignin model compounds that served as the sole carbon sources were 4-hydroxybenzoic acid and vanillic acid. It was found that the microbial cells not only proliferated but also began lipid accumulation to oleaginicity levels. The lipids formed were extracted for transesterification and fatty acid methyl esters (FAME) analyses. The results showed potential conversion to biodiesel and the microbial strains used depicted discrete substrate metabolism along with characteristic product profiles. Kosa and Ragauskas [105] also suggested a metabolic pathway for lignin bioconversion to lipids that would prove innovative for an integrated lignin conversion. The two forms of lignin-based feedstocks used in the study were ethanol organosolv lignin and ultrasonicated ethanol organosolv lignin that employed Rhodococcus opacus for bioconversion. Both the lignin feedstocks were found to be potential sources and the maximum lipid yield obtained was 4.1%.

There have been further studies by Wells et al. [106] using Rhodococcus opacus DSM 1069 that utilized pinecone pretreatment effluent as the only source of energy and carbon for a duration of 120 h with 1.5 w/v% of solid concentration. The oils formed were a mixture of oleic acid, stearic acid, fatty acid and palmitic acid. This study paved the way for the use of lignocellulosic pretreatment waste as the feedstock for its conversion to biodiesel using microorganisms. Certain lignocellulosic biomass can contain as high as 17.5% of lignin and 67% of carbohydrates trapped in their cell walls, such as Saccharum spontaneum. Degradation of lignin in Saccharum spontaneum (a grass indigenous to Indian subcontinent) with the help of laccase was accomplished by Rajaka and Banerjee [107] to avail this bountiful source of carbohydrates that can be hydrolyzed for potential use. The process parameters were optimization using response surface method (RSM). Maximum delignification (~ 84.7%) of biomass with an initial lignin content of 17.5% was attained after 6.2 h.

Kateava et al. [108] showed the ability of anaerobic bacterium Caldicellulosiruptor bescii to simultaneously convert lignin and carbohydrates in unpretreated switchgrass to aromatic compounds. Another interesting outcome was that the microorganisms could produce enzymes that affect the significant content of the biomass cell wall such as xyloglucans, pectin and rhamnogalacturonan. The enzymes produced by thermophilic microorganisms can act towards the simultaneous bioconversion of hemicellulose, cellulose and lignin, which can prove significant to the industrial bioconversion of lignocellulosic biomass.

Genetic modifications of the feedstock to produce better results have also been considered. Fu et al. [109] reported that modification in switchgrass caffeic acid O-methyltransferase gene could increase the ethanol yields by reducing the lignin content. These modified grass species do not require very severe pretreatment conditions and approximately 300% less cellulase dose for an equivalent yield of the product with the help of saccharification and yeast fermentation. Additionally, it was found that the fermentation of the acid-pretreated and genetically modified switchgrass in its dilute form with the help of Clostridium thermocellum gave better yields without adding any enzyme than the yields for unmodified switchgrass.

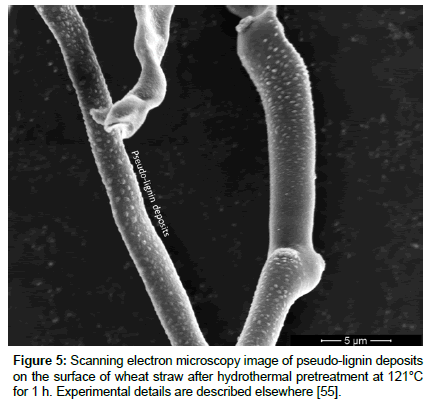

Lignin bioconversion depends on its source and chemical properties as much as other factors. Therefore, it is essential to highlight the categories of lignin that will inhibit its biological conversion. In this context, pseudo-lignin has been highlighted. Pseudo-lignin can be defined as an aromatic material that produces positive Klason lignin, which is not extracted from native lignin. The pseudo-lignin is formed during the dilute acid pretreatment of holocellulose (cellulose and hemicellulose) and causes hindrance in lignin conversion. Nanda et al. [55] performed a comparative evaluation of the structural chemistry of pinewood, wheat straw and Timothy grass treated with liquid hot water and acidified sodium chlorite. They found that because of hot aqueous treatment, hemicellulose was removed from the biomass, as it is hydrophilic and easy to hydrolyze. On the other hand, pseudo-lignin was found as spherical droplets deposited on the surface of biomass fibers through re-polymerization in hydrothermal pretreatment (Figure 5). The deposition of pseudo-lignin on the cell surface of pretreated biomasses has also been reported by several other authors [86,110,111].

Figure 5: Scanning electron microscopy image of pseudo-lignin deposits on the surface of wheat straw after hydrothermal pretreatment at 121°C for 1 h. Experimental details are described elsewhere [55].

Hu et al. [110] studied the chemistry of the formation of pseudolignin from α-cellulose and poplar holocellulose after pretreatment with dilute acid. The molecular weights and chemical structures (e.g. aromatic, carbonyl, carboxylic and methoxy) of pseudo-lignin from holocellulose were found to be the similar using different pretreatment conditions. The study supported that the presence and structural formation of pseudo-lignin significantly inhibit lignin bioconversion through enzymatic hydrolysis. The high the severity of pretreatment conditions higher was the Klason lignin formation. Thus, pretreatments that were catalyzed using acids led to the formation of pseudo-lignin with high Klason lignin content that proved detrimental to the enzymatic bioconversion of lignin [112].

Thermochemical Conversion of Lignin

Pyrolysis

Pyrolysis is a well-established thermochemical technology that leads to biomass-to-liquid fuel products. The thermal degradation of lignin advocates fast pyrolysis as an effective route to obtaining bio-oils that can be used for synthesizing valued polymers, resins and adhesives. The pyrolytic product contents can vary depending on the composition and properties of lignin, pyrolysis conditions (temperature and catalyst) and the reactor design [17]. The pyrolysis of lignin is a two-step mechanism, which involves thermal cracking and re-oligomerization. The cracking at high temperatures is subjected to the macromolecules of lignin followed by vapor condensation that lead to the formation of monomeric phenol vapors. During the second step, the monomers formed undergo re-oligomerization leads to the formation of pyrolysis oil predominantly comprising of dimeric and oligomeric products [113].

A few studies on pyrolysis of lignin have been carried out since the last two decades with focus on bio-oil, biochar and producer gas [114-116]. The gas yields are reported to increase with an increase in pyrolysis temperature. However, the high heating rates hinder CH4 formation [115]. According to Ferdous et al. [115], lignin pyrolysis can yield H2 as high as 25 mol%, which increases with rising pyrolysis temperature. Syngas, which is composed of H2 and CO, can be further converted to green diesel, ethanol, butanol and other hydrocarbons through Fischer-Tropsch catalysis, which is a mature gas-to-liquid (GTL) technology. Syngas can also be converted to bioethanol through syngas fermentation using Clostridium spp. [2,57].

Limited work has been done towards understanding the physicochemical properties of chars obtained from lignin pyrolysis. The char is reported to have an extremely condensed aromatic structure that keeps ~ 50% biomass energy entrapped in it [116]. The increase in pyrolysis temperature reduces the char yields as more product gases are formed at increased temperatures due to the cleavage of hydroxyl, aliphatic, methoxyl and carbonyl groups [117,118]. During pyrolysis of lignin, methoxyl group is a major contributor to char formation. Chu et al. [119] studied the pyrolysis of the β-O-4 type lignin model compound and reported that polymerization reaction resulted in char formation. The smaller radicals underwent polymerization mechanism during pyrolysis of the β-O-4 type lignin model polymer at 250-550°C. The side functional groups (i.e. methoxyl and hydroxyl groups) when eliminated led to char formation after the termination of polymerization.

The liquid products from lignin pyrolysis include guaiacyl derivatives, coniferyl alcohol, coniferaldehyde, syringaldehyde, sinapyl alcohol, p-vinylphenol depending on the type of lignin (hardwood or softwood) [116,120-122]. The impact of pyrolysis temperature and heating rates on product yield and distribution has been reported elsewhere [123,124]. They performed slow pyrolysis (2°C/min for 30 min) and fast pyrolysis (450°C/min for 30 s) of pinewood, wheat straw and Timothy grass in a wire-mesh fixed-bed tubular reactor. The slow pyrolysis led to 18-24 wt% bio-oil yield and 41-44 wt% biochar yield, whereas fast pyrolysis resulted in 40-48 wt% bio-oil yield and 21-24 wt% biochar yield. Furthermore, oxygenates and nitrogenous compounds were predominantly found in slow pyrolysis bio-oil, while fast pyrolysis bio-oil contained aliphatics, monoaromatics and polyaromatics and demonstrated high heating value [124]. From a laser micro-pyrolysis gas chromatography-mass spectrometer (GC-MS) study on pyrolyzed Douglas fir and water oak lignin, 4-methyl-guaiacol, guaiacol, vinyl guaiacol, vanillin and eugenol were the major components obtained [125].

Liquefaction

Liquefaction typically operates at pressure and temperature ranges of 1-20 MPa and 250°C-450°C, respectively [48]. While pyrolysis results in highly oxygenated and hydrated bio-crude oil, liquefaction produces less oxygenated and relatively dehydrated bio-crude oil. The low oxygen and moisture contents in liquefaction-derived bio-oils reduce the necessity of upgrading techniques such as hydrotreating and hydrodeoxygenation [2,57]. The high heat of vaporization in biomass due to its high-water content makes the pyrolysis treatment challenging and limits the potential of biomass as a feedstock. The high moisture content in biomass leads to the high-water content in the aqueous phase of the pyrolysis oil. This necessitates water removal from the feedstock and bio-oil, which could otherwise influence the overall economy of the process. The application of pyrolysis requires biomass pretreatment to avoid moisture-related problems. Atmospheric drying, followed by mechanical drying and/or solar drying are usually considered for reducing the moisture content of biomass. On the contrary, biomass liquefaction is one of the most efficient methods of yielding bio-oil with lower water content.

Another analog to liquefaction is hydrothermal liquefaction, which results in better biomass conversion rates and yields relatively pure products. At hydrothermal conditions, fluid in biomass can possess high solvation power and they attain suitable properties such as high heat, high density and good mass transfer capabilities [126]. Liquefaction is an environmentally benign process because it does not emit any obnoxious gases such as ammonia and nitrous oxides. During hydrothermal oxidation, the heteroatoms are converted to byproducts that do not pose any threat to the environment. Moreover, the medium of liquefaction is water, a green solvent in its liquid state, as well as subcritical and supercritical states [127-129].

Hydrothermal liquefaction results in the hydrolysis and subsequent denaturation of biomass macromolecules into smaller molecules. Most of the fragmented molecules are usually unstable and reactive, hence they tend to re-polymerize into larger compounds [130]. This process leads to the removal of oxygen from biomass through deoxygenation, dehydration and decarboxylation. Therefore, the bio-oil that is produced from the liquefaction of dehydrated biomass contains less oxygen and moisture.

In case of direct liquefaction, the biomass is completely transformed to liquid fuel without undergoing gasification. Kobayashi et al. [131] have studied the liquefaction of steamed lignin, alkali lignin and their mixtures with cellulose powder in the presence of polyhydric alcohol. The liquefaction of wood led to the formation of products like N, N-dimethylformamide. Li et al. [132] studied the selective liquefaction of lignin that was extracted from the residue from bio-ethanol production. It has been reported that liquefaction process has a great selectivity towards lignin. Liquefaction of lignin using polyethylene glycol has led to the formation of polyether polyol [133].

Gasification

The thermochemical process that involves the conversion of carbonaceous solids such as biomass, char, coal etc. or liquids (oil, tar etc.) on their reaction with steam or air to yield gaseous products (e.g. H2, CO, CO2, CH4 and C2+) is called gasification. In simple words, gasification is a biomass-to-gas conversion technology that can use air, inert gas, steam or water as the reaction medium. The product gas from gasification is usually termed as producer gas or synthetic gas (syngas) based on the reaction medium. For instance, the highpressure gasification of steam yields syngas, whereas producer gas is a gaseous product when the gasification is carried out in the presence of air. High levels of N2 in the producer gas as compared to H2, CO2 and CO make it suitable for heat or electricity generation. On the other hand, syngas is composed of H2, CO, CH4, and CO2 can be used as a gaseous fuel and a precursor for generating higher alcohols and long-chains hydrocarbons. As mentioned earlier, syngas can be converted to alcohols, hydrocarbons and green diesel through Fischer-Tropsch catalysis [134]. Fermentation of syngas by specific bacteria (Clostridium spp.) is also a biological means to produce bioethanol from syngas [135].

Hydrothermal gasification involves the application of subcritical or supercritical water as the reaction medium, reactant and catalyst. Subcritical water has its temperature (T) <374°C and pressure (P) <22.1 MPa, whereas supercritical water is characterized by T >374°C and P >22.1 MPa [136]. Hydrothermal gasification is advantageous over thermochemical gasification in many aspects, a few of which include: (i) rapid biomass hydrolysis and degradation of macromolecules, (ii) relatively low temperature requirement, (iii) high reaction rates, (iv) enhanced biomass solubility in aqueous medium, (v) abridged char and tar formation, (vi) lower chances of re-polymerization of reactive components [137]. Since the medium of gasification is water, high-moisture containing biomass can be used, which can reduce the cost of biomass drying like hydrothermal liquefaction. Cellulose, hemicellulose and lignin in biomass are found to be highly soluble in hydrothermal gasification resulting in high yields of H2-rich syngas [138].

Oxygen in trace amounts can be added to the gasification reactants to help the exothermic oxidation heat towards steamreforming reaction, which is endothermic in nature. The other advantage of adding oxygen is to reduce catalyst deactivation due to coking as oxygen can help to burn coke. As biomass has higher oxygen content than coal, it forms an excellent gasification feedstock at lower temperatures [139]. Catalytic biomass gasification is a very popular and extensively studied conversion technique.

Lignin gasification with 4-propylphenol in the presence of supported metal catalyst was carried out at supercritical water conditions. Lignin gasification could be divided into two steps: (i) lignin decomposition, and (ii) gasification of low molecular weight compounds. The rate of lignin gasification was found to be impacted by water density [140]. There are several studies conducted to produce hydrogen from lignin gasification using metal catalysts [140-145]. Furusawa et al. [144] produced H2 from lignin gasification using Ni/MgO catalyst. The 10 wt% Ni/MgO catalyst at 600°C gave the best catalytic activity and carbon yield (30 wt%). Ni/MgO was found to be a promising catalyst for lignin gasification in supercritical water. Osada et al. [142] reported 30% gas yield from the gasification of lignin and cellulose at a low temperature (400°C) using Ru catalyst. The major gas product was CH4 with low char formation. Other uses of lignin gasification have also been explored such as producing activated carbon from CO2 partial gasification of kraft lignin [146]. There are comprehensive reviews available on activated carbon, adsorbents, fine chemicals and other industrially relevant products from lignin gasification [65,147,148].

Supercritical water gasification of lignin results in the generation of phenolics, which are catalyzed by the dissociated ionic components of water i.e. H+ and OH– ions. Because of hydrolysis and dealkylation, lignin also produces phenols, formaldehyde and reactive low molecular weight compounds [2]. The reactive low molecular weight compounds with formaldehyde undergo cross-linking to yield high molecular weight compounds. The ether-based components produced from lignin hydrolysis result in the organic phase of the oil. Hydrolysis and dealkylation of guaiacols and syringols produce methanol and catechols that result in the aqueous phase of the liquid products. The intermediates and degraded components could repolymerize at high temperatures and longer residence time to form phenolic char [149]. Amendment of phenol during supercritical water gasification of lignin is found to improve lignin degradation by considerably inhibiting the re-polymerization of the highly reactive components [150]. Because of phenol addition, the higher and substituted phenols such as catechols, cresols and guaiacols deform to form stable phenolic compounds.

The phenolic char is highly aromatic and carbonaceous, which are also formed by the reaction between denatured phenolics and aldehydes. The non-condensable components of lignin gasification end up in the gas phase that is mostly combustible due to the presence of H2, CO, CH4 and C2+. Hydrothermal gasification of lignin in nearcritical water generates significant amounts of CO2. Hydrothermal gasification of lignin at a high feed concentration also decreases H2 and CO yields, while increasing CH4 levels due to methanation and hydrogenation. However, H2 yields can be enhanced at high gasification temperature, while also reduced CO concentration due to water-gas shift reaction [136].

Microwave-Assisted Conversion of Lignin

Microwaves are electromagnetic waves formed within a frequency band between 300 MHz and 300 GHz [151]. The mechanism of microwave-assisted heating depends on conduction, dipolar or orientation polarization and interfacial polarization. Microwave irradiation causes the electromagnetic waves to oscillate rapidly leading to the alignment of polar molecules in the radiation field. Moreover, dipolar polarization leads to the continuous alignment of the polar molecules inside the material, which generates heat energy [152,153]. In microwave irradiation, the wave interactions within the exposed material lead to the heat transfer and a higher energy yield compared to the conventional ovens, which transmit heat by the conduction and convention mechanisms. In conventional heating techniques, the heat energy is transferred from the exposed material’s surface toward its center by conduction and convention, whereas microwave irradiation converts electromagnetic energy into thermal energy rather than only heating.

Compared to conventional heating technologies, the advantages of microwave heating include shorter residence time, efficient and faster heat transfer, precise and controlled heating, easier operations, less maintenance and environmentally friendly process [154]. However, microwave-assisted heating has a few disadvantages, which include (i) poor distribution of microwave radiation owing to the exposed material’s non-homogeneity, (ii) non-uniform heating, and (iii) poor penetration of microwave radiation in bulk and highly-dense materials [155-157]. One of the key determinants associated with the adoption of microwave pretreatment technology is its operating cost.

Microwave pretreatment of lignocellulosic biomass is a very effective technique that can be used independently or coupled with other thermochemical conversion technologies to transform lignin to many useful products. Microwave-assisted alkali pretreatment can efficiently penetrate the biomass and vibrate its molecules. The rapid vibration and oscillation of polar molecules can lead to heating and disruption of the lignocellulosic structure. Microwave pretreatment has a potential to selectively remove lignin consequently improving the access of cellulolytic enzyme to degrade cellulose and increase sugar yields.

During microwave-assisted conversion of lignin, there is a direct interaction amidst the microwave radiations and the particles of the compressed material. This consequently converts the electromagnetic energy to the heat transfer within the dielectric substances. Unlike other forms of heating, in microwave-assisted biomass conversion, the irradiations are not conducted into the substance from a source that is external, which leads to instant bulk heating. This non-contact technique of heating the substance with the help of electromagnetic radiations can avoid challenges related to direct heating via convection. Moreover, through microwave treatment, a large amount of heat can be transferred to the interior of the substance without generating a thermal gradient. Thus, microwave conversions are quick and more effective than any other technique enabling the conversion at lower temperatures and less reaction time.

Many reports suggest that the microwave-assisted lignin conversion is highly promising as a next-generation biomass pretreatment technology [158-163]. Sequeiros et al. [158] performed microwave-assisted liquefaction of pruned lignin derived from the olive tree at varying conditions of temperature, catalyst concentration and reaction time. The organosolv lignin feedstock and product polyols were characterized using various methods. Microwave conversion is found to be more effective than the traditional method of lignin refluxing. Gassara et al. [159] quantified lignin present in the residues of apple pomace through microwave conversion technique. The microwaves assisted in the cleavage of the bonds between lignin and carbohydrates. Statistical technique (response surface method) was used to optimize the process parameters. The optimal conditions for lignin digestion were reported to be 3 MPa, 15 min and 170°C.

Dong et al. [164] reported their observations on the microwaveassisted conversion of black liquor lignin with formic acid. The product, comprising a mixture of two bio-oils, achieved 64.1% yield after 30 min of reaction at 160°C. Various characterization techniques were used to identify the properties of the liquid product along with the solid residue. A reaction mechanism was predicted based on the obtained results, which focused on the microwave conversion of lignin using acid and highlighted the kinetics of the primary cracking and re-polymerization of oligomeric substances and formation of char.

Toledano et al. [165] studied the microwave-assisted lignin conversion using the de-polymerization route to smaller aromatics. Different loadings of metal nanoparticles (e.g. Ni, Pt, Pd and Ru) were doped on mesoporous Al-SBA-15 to synthesize the catalyst for an efficient lignin conversion. The products obtained were categorized as bio-oil, biochar and unconverted lignin. The ultimate objective of the study was to maximize the production of bio-oil using different catalysts. The results demonstrated a significant role of metal nanoparticles in the hydrogenolysis reaction of lignin. Along with other products, the phenolic compounds from lignin such as mesitol, syringaldehyde, desaspidinol and aspidinol were obtained. The biooil comprised of monomers, dimers and trimers. Among most of the metals used, nickel was reported to have the best results for lignin depolymerization.

Conclusions

Lignocellulosic wastes from forestry, agricultural residues and energy crop systems are abundantly available and considered potential feedstocks for biofuel production through thermochemical and biological conversion. There are some challenges towards the efficient disposal of the accumulated lignocellulosic residues. Several studies have been conducted towards understanding the physical and chemical nature of lignin and the biological and chemical routes of lignin conversion. Lignin is certainly one of the most significant biomass that can be utilized to produce fuel as well as other biomaterials. However, lignin appears to hinder the hydrolysis of lignocellulosic biomass as it glues cellulose and hemicellulose together in a firm biopolymeric framework. Except for alkalis, lignin is relatively insoluble in hot water, acids and solvents. Therefore, a delignification step is extremely crucial to remove the branched polymeric lignin from the biomass followed by pretreatment and enzymatic hydrolysis to release the fermentable polysaccharides.

The use of ligninolytic fungi and their enzymes have been identified as a low-cost route for enzymatic hydrolysis of lignin-rich substrates. Several valued products can be obtained from ligneous biomass, a few of which include fuels, organic acids, polysaccharides, nutraceuticals, etc. The thermochemical conversion of lignin-rich materials chiefly yields biofuels in the form of bio-oils, biodiesel and syngas, as well as aromatic char. The biochar that is generated as a byproduct of pyrolysis and gasification of lignin can be used as a precursor to produce several carbon-based engineered materials such as activated carbon, carbon nanotubes, carbon nanohorns, etc. Lignin or its derivatives can also be used as biocomposite, binder or precursor for bioplastics, pesticides, insecticides and other industrially relevant materials. Lignin is an attractive bioresource for biological and thermochemical conversion, therefore more research in improving the existing conversion technologies or developing new processes could help deploy this valuable material. The notion of utilizing lignocellulosic wastes to extract lignin and subsequently converting it to biofuel, biomaterials and biochemicals can aid towards the escalating energy demands worldwide and help reduce the environmental concerns that are often raised while putting fossil fuels to use.

Acknowledgements

The authors acknowledge the funding provided by Natural Sciences and Engineering Research Council of Canada (NSERC) and Canada Research Chair (CRC) program.

References

- Demirbas MF (2006) Current technologies for biomass conversion into chemicals and fuels. Energ Source Part A 28: 1181-1188.

- Nanda S, Mohammad J, Reddy SN, Kozinski JA, Dalai AK (2014) Pathways of lignocellulosic biomass conversion to renewable fuels. Biomass Conversion and Biorefinery 4: 157-191.

- Nanda S, Azargohar R, Dalai AK, Kozinski JA (2015) An assessment on the sustainability of lignocellulosic biomass for biorefining. Renew Sust Energ Rev 50: 925-941.

- Johnson E (2009) Goodbye to carbon neutral: getting biomass footprints right. Env Imp Assess 29: 165-168.

- Sánchez C (2009) Lignocellulosic residues: biodegradation and bioconversion by fungi. Biotechnol Adv 27: 185-194.

- Sahoo K, Mani S, Das L, Bettinger P (2018) GIS-based assessment of sustainable crop residues for optimal siting of biogas plants. Biomass Bioenerg 110: 63-74.

- Pauly M, Keegstra K (2008) Cell-wall carbohydrates and their modification as a resource for biofuels. Plant J 54: 559-568.

- Wu X, McLaren J, Madl R, Wang D (2010) Biofuels from lignocellulosic biomass. Sustainable Biotechnology: Sources of Renewable Energy, Springer, Germany.

- Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48: 3713-3729.

- Mohanty P, Pant KK, Naik SN, Parikh J, Hornung A, et al. (2014) Synthesis of green fuels from biogenic waste through thermochemical route - The role of heterogeneous catalyst: A review. Renew Sust Energ Rev 38: 131-153.

- Lora JH, Glasser WG (2002) Recent industrial applications of lignin: A sustainable alternative to nonrenewable materials. J Polym Environ 10: 39-48.

- Sannigrahi P, Ragauskas AJ (2011) Characterization of fermentation residues from the production of bio-ethanol from lignocellulosic feedstocks. J Biobased Mater Bio 5: 514-519.

- Stewart D (2008) Lignin as a base material for materials applications: Chemistry, application and economics. Ind Crop Prod 27: 202-207.

- Ayyachamy M, Collier J, Tuohy MG (2013) Lignin: untapped biopolymers in biomass conversion technologies. Biomass Conversion Biorefining 3: 255-269.

- Strassberger Z, Tanase S, Rothenberg G (2014) The pros and cons of lignin valorisation in an integrated biorefinery. RSC Adv 4: 25310-25318.

- Chatterjee S, Saito T, Rios O, Johs A (2014) Lignin based carbon materials for energy storage applications. Green Technologies for the Environment, Am Chem S, Washington, USA.

- Nanda S, Dalai AK, Berruti F, Kozinski JA (2016) Biochar as an exceptional bioresource for energy, agronomy, carbon sequestration, activated carbon and specialty materials. Waste Biomass Valori 7: 201-235.

- Shatkin JA, Wegner TH, Bilek EMT, Cowie J (2014) Market projections of cellulose nanomaterial-enabled products − Part 1: Applications. Tappi J 13: 9-16.

- Baurhoo B, Phillip L, Ruiz-Feria CA (2007) Effects of purified lignin and mannan oligosaccharides on intestinal integrity and microbial populations in the ceca and litter of broiler chickens. Poultry Sci 86: 1070-1078.

- Gibson GR, Roberfroid MB (1995) Dietary modulation of the human colonic microbiota: Introducing the concept of prebiotics. J Nutr 125: 1401-1412.

- Ugartondo V, Mitjans M, Vinardell MP (2008) Comparative antioxidant and cytotoxic effects of lignins from different sources. Bioresource Technol 99: 6683-6687.

- Vinardell MP, Ugartondo V, Mitjans M (2008) Potential applications of antioxidant lignins from different sources. Ind Crop Prod 27: 220-223.

- Harada H, Sakagami H, Nagata K, Ohhara T, Kawazoe Y, et al. (1991) Possible involvement of lignin structure in anti-influenza virus activity. Antivir Res 15: 41-49.

- Mukoyama A, Ushijima H, Unten S, Nishimura S, Yoshihara M, et al. (1991) Effect of pine seed shell extract on rotavirus and enterovirus infections. Lett Appl Microbiol 13: 109-111.

- Mitsuhashi S, Kishimoto T, Uraki Y, Okamoto T, Ubukata M (2008) Low molecular weight lignin suppresses activation of NF-kappa B and HIV-1 promoter. Bioorgan Med Chem 16: 2645-2650.

- Sakagami H, Kushida T, Oizumi T, Nakashima H, Makino T (2010) Distribution of lignin-carbohydrate complex in plant kingdom and its functionality as alternative medicine. Pharmacol Therapeut 128: 91-105.

- Wu RL, Wang XL, Li F, Li HZ, Wang YZ (2009) Green composite films prepared from cellulose, starch and lignin in room temperature ionic liquid. Bioresource Technol 100: 2569-2574.

- Calgeris I, Cakmakci E, Ogan A, Kahraman MV, Kayaman-Apohan N (2012) Preparation and drug release properties of lignin-starch biodegradable films. Starch 64: 399-407.

- Chen P, Zhang LN, Peng SP, Liao B (2006) Effects of nanoscale hydroxypropyl lignin on properties of soy protein plastics. J Appl Polym Sci 101: 334-341.

- Chen F, Dixon RA (2007) Lignin modification improves fermentable sugar yields for biofuel production. Nat Biotechnol 25: 759-761.

- Johnson DK, Chornet E, Zmierczak W, Shabtai J (2002) Conversion of lignin into a hydrocarbon product for blending with gasoline. Fuel Chemistry Division Preprints 47: 380-381.

- Ben H, Mub W, Deng Y, Ragauskas AJ (2013) Production of renewable gasoline from aqueous phase hydrogenation of lignin pyrolysis oil. Fuel 103: 1148-1153.

- Lumadue MR, Cannon FS, Brown NR (2012) Lignin as both fuel and fusing binder in briquetted anthracite fines for foundry coke substitute. Fuel 97: 869-875.

- Qin W, Kadla JF (2011) Effect of organoclay reinforcement on lignin-based carbon fibers. Ind Eng Chem Res 50: 12548-12555.

- Maradur SP, Kim CH, Kim SY, Kim BH, Kim WC, et al. (2012) Preparation of carbon fibers from a lignin copolymer with polyacrylonitrile. Synthetic Met 162: 453-459.

- Yang Q, Pan X, Huang F, Li K (2010) Fabrication of high-concentration and stable aqueous suspensions of graphene nanosheets by noncovalent functionalization with lignin and cellulose derivatives. J Phys Chem C 114: 3811-3816.

- Zazo JA, Bedia J, Fierro CM, Pliego G, Casas JA, et al. (2012) Highly stable Fe on activated carbon catalysts for CWPO upon FeCl3 activation of lignin from black liquors. Catal Today 187: 115-121.

- Mahmoudi K, Hamdi N, Kriaa A, Srasra E (2012) Adsorption of methyl orange using activated carbon prepared from lignin by ZnCl2 treatment. Russ J Phys Ch 86: 1294-1300.

- Li Y, Ragauskas AJ (2012) Kraft lignin-based rigid polyurethane foam. J Wood Chem Technol 32: 210-224.

- Houghton TP, Thompson DN, Hess JR, Lacey JA, Wolcot MP, et al. (2004) Fungal upgrading of wheat straw for straw-thermoplastics production. Appl Biochem Biotech 113: 71-93.

- Biely P, Kremnicky L (1998) Yeasts and their enzyme systems degrading cellulose, hemicelluloses and pectin. Food Technol Biotech 36: 305-312.

- Nanda S, Mohanty P, Pant KK, Naik S, Kozinski JA, et al. (2013) Characterization of North American lignocellulosic biomass and biochars in terms of their candidacy for alternate renewable fuels. Bioenerg Res 6: 663-677.

- Demirbas A (2004) Combustion characteristics of different biomass fuels. Prog Energ Combust 30: 219-230.

- Wei L, Xu S, Zhang L, Zhang H, Liu C, et al. (2006) Characteristics of fast pyrolysis of biomass in a free fall reactor. Fuel Process Technol 87: 863-871.

- Raveendran K, Ganesh A, Khilar KC (1995) Influence of mineral matter on biomass pyrolysis characteristics. Fuel 74: 1812-1822.

- Scurlock JMO, Dayton DC, Hames B (2000) Bamboo: An overlooked biomass resource? Biomass Bioenerg 19: 229-244.

- Tamaki Y, Mazza G (2010) Measurement of structural carbohydrates, lignins, and micro-components of straw and shives: effects of extractives, particle size and crop species. Ind Crop Prod 31: 534-541.

- Huber GW, Iborra S, Corma A (2006) Synthesis of transportation fuels from biomass: chemistry, catalysts, and engineering. Chem Rev 106: 4044-4098.

- Naik S, Goud VV, Rout PK, Jacobson K, Dalai AK (2010) Characterization of Canadian biomass for alternative renewable biofuel. Renew Energ 35: 1624-1631.

- Demirbaş A (2005) Thermochemical conversion of biomass to liquid products in the aqueous medium. Energ Source 27: 1235-1243.

- Brebu M, Ucar S, Vasile C, Yanik J (2010) Co-pyrolysis of pine cone with synthetic polymers. Fuel 89: 1911-1918.

- Nigam JN (2002) Bioconversion of water-hyacinth (Eichhornia crassipes) hemicellulose acid hydrolysate to motor fuel ethanol by xylose-fermenting yeast. J Biotechnol 97: 107-116.

- Sjöström E (1993) Wood chemistry: fundamentals and applications. Academic Press, San Diego, USA.

- Correa AC, de Morais Teixeira E, Pessan LA, Mattoso LHC (2010) Cellulose nanofibers from curaua fibers. Cellulose 17: 1183-1192.

- Nanda S, Maley J, Kozinski JA, Dalai AK (2015) Physico-chemical evolution in lignocellulosic feedstocks during hydrothermal pretreatment and delignification. J Biobased Mater Bio 9: 295-308.

- Vassilev SV, Baxter D, Andersen LK, Vassileva CG, Morgan TJ (2012) An overview of the organic and inorganic phase composition of biomass. Fuel 94: 1-33.

- Nanda S, Kozinski JA, Dalai AK (2016) Lignocellulosic biomass: A review of conversion technologies and fuel product. Curr Biochem Eng 3: 24-36.

- Gibson LJ, Soc JR (2012) The hierarchical structure and mechanics of plant materials. J R Soc Interface 9: 2749-2766.

- Hallac BB, Ragauskas AJ (2011) Analyzing cellulose degree of polymerization and its relevancy to cellulosic ethanol. Biofuel Bioprod Bior 5: 215-255.

- Carrier M, Loppinet-Serani A, Denux D, Lasnier JM, Ham-Pichavant F, et al. (2011) Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. Biomass Bioenerg 35: 298-307.

- Nanda S, Azargohar R, Kozinski JA, Dalai AK (2014) Characteristic studies on the pyrolysis products from hydrolyzed Canadian lignocellulosic feedstocks. Bioenerg Res 7: 174-191.

- Pu Y, Zhang D, Singh PM, Ragauskas AJ (2008) The new forestry biofuels sector. Biofuel Bioprod Bior 2: 58-73.

- Novaes E, Kirst M, Chiang V, Winter-Sederoff H, Sederoff R (2010) Lignin and biomass: A negative correlation for wood formation and lignin content in trees. Plant Physiol 154: 555-561.

- Hon DNS (1996) Chemical modification of lignocellulosic material. Marcel Dekker, New York, USA.

- Suhas, Carrott PJM, Carrott MMLR (2007) Lignin - from natural adsorbent to activated carbon: A review. Bioresour Technol 98: 2301-2312.

- Kadla JF, Kubo S, Gilbert RD, Venditti RA (2012) Lignin-based carbon fibers. Chemical Modification, Properties, and Usage of Lignin, Springer, New York, USA.

- Laureano-Perez L, Teymouri F, Alizadeh H, Dale BE (2005) Understanding factors that limit enzymatic hydrolysis of biomass. Appl Biochem Biotech 121: 1081-1099.

- Balan V, Sousa LD, Chundawat SPS, Marshall D, Sharma LN, et al. (2009) Enzymatic digestibility and pretreatment degradation products of AFEX-treated hardwoods (Populus nigra). Biotechnol Progr 25: 365-375.

- Hu F, Ragauskas A (2012) Pretreatment and lignocellulosic chemistry. Bioenerg Res 5: 1043-1066.

- Reddy SN, Nanda S, Dalai AK, Kozinski JA (2014) Supercritical water gasification of biomass for hydrogen production. Int J Hydrogen Energ 39: 6912-6926.

- Sun Y, Cheng JJ (2005) Dilute acid pretreatment of rye straw and bermudagrass for ethanol production. Bioresource Technol 96: 1599-1606.

- Dien BS, Jung HJG, Vogel KP, Casler MD, Lamb JFS, et al. (2006) Chemical composition and response to dilute-acid pretreatment and enzymatic saccharification of alfalfa, reed canarygrass, and switchgrass. Biomass Bioenerg 30: 880-891.

- Guo GL, Chen WH, Chen WH, Men LC, Hwang WS (2008) Characterization of dilute acid pretreatment of silvergrass for ethanol production. Bioresour Technol 99: 6046-6053.

- Nanda S, Dalai AK, Kozinski JA (2014) Butanol and ethanol production from lignocellulosic feedstock: Biomass pretreatment and bioconversion. Energy Sci Eng 2: 138-148.

- Lloyd TA, Wyman CE (2005) Combined sugar yields for dilute sulfuric acid pretreatment of corn stover followed by enzymatic hydrolysis of the remaining solids. Bioresour Technol 96: 1967-1977.

- Qureshi N, Ezeji TC, Ebener J, Dien BS, Cotta MA, et al. (2008) Butanol production by Clostridium beijerinckii. Part I: Use of acid and enzyme hydrolyzed corn fiber. Bioresour Technol 99: 5915-5922.

- Roberto IC, Mussatto SI, Rodrigues RCLB (2003) Dilute-acid hydrolysis for optimization of xylose recovery from rice straw in a semi-pilot reactor. Ind Crop Prod 17: 171-176.

- Karimi K, Kheradmandinia S, Taherzadeh MJ (2006) Conversion of rice straw to sugars by dilute-acid hydrolysis. Biomass Bioenerg 30: 247-253.

- Qureshi N, Saha BC, Cotta MA (2007) Butanol production from wheat straw hydrolysate using Clostridium beijerinckii. Bioprocess Biosyst Eng 30: 419-427.

- Zhu JY, Pan X, Zalesny RS Jr (2010) Pretreatment of woody biomass for biofuel production: energy efficiency, technologies, and recalcitrance. Appl Microbiol Biot 87: 847-857.

- Lavarack BP, Griffin GJ, Rodman D (2002) The acid hydrolysis of sugarcane bagasse hemicellulose to produce xylose, arabinose, glucose and other products. Biomass Bioenerg 23: 367-380.

- Rodriguez-Chong A, Ramirez JA, Garrote G, Vazquez M (2004) Hydrolysis of sugar cane bagasse using nitric acid. J Food Eng 61: 143-152.

- Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, et al. (2011) Determination of structural carbohydrates and lignin in biomass (Technical Report NREL/TP-510-42618). National Renewable Energy Laboratory (NREL), Colorado, USA.

- Technical Association of the Pulp and Paper Industry, Tappi (2011) Acid-insoluble lignin in wood and pulp (TAPPI test method T222 om-88). Tappi, Atlanta, USA.

- Chen W, Yu H, Liu Y, Chen P, Zhang M, et al. (2011) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohyd Polym 83: 1804-1811.

- Kristensen JB, Thygesen LG, Felby C, Jorgensen H, Elder T (2008) Cell-wall structural changes in wheat straw pretreated for bioethanol production. Biotechnol Biofuels 1: 5.

- Lawther JM, Sun R, Banks WB (1996) Fractional characterization of alkali-labile lignin and alkali-insoluble lignin from wheat straw. Ind Crop Prod 5: 291-300.

- Ezeji T, Qureshi N, Blaschek HP (2007) Butanol production from agricultural residues: Impact of degradation products on Clostridium beijerinckii growth and butanol fermentation. Biotechnol Bioeng 97: 1460-1469.

- Qureshi N, Saha BC, Dien B, Hector RE, Cotta MA (2010) Production of butanol (a biofuel) from agricultural residues: Part I - Use of barley straw hydrolysate. Biomass Bioenerg 4: 559-565.

- Qureshi N, Saha BC, Hector RE, Dien B, Hughes S, et al. (2010b) Production of butanol (a biofuel) from agricultural residues: Part II - Use of corn stover and switchgrass hydrolysates. Biomass Bioenerg 34: 566-571.

- Hammel KE (1997) Fungal Degradation of lignin. Plant Litter Quality and Decomposition (Cab International, USA.

- Gong M, Nanda S, Hunter HN, Zhu W, Dalai AK, et al. (2017) Lewis acid catalyzed gasification of humic acid in supercritical water. Catal Today 291: 13-23.

- Gong M, Nanda S, Romero MJ, Zhu W, Kozinski JA (2017b) Subcritical and supercritical water gasification of humic acid as a model compound of humic substances in sewage sludge. J Supercrit Fluid 119: 130-138.

- Wong DW (2009) Structure and action mechanism of ligninolytic enzymes. Appl Biochem Biotechnol 157: 174-209.

- Well Jr T, Ragauskas AJ (2012) Biotechnological opportunities with the β-ketoadipate pathway. Trends Biotechnol 30: 627-637.

- de Gonzalo G, Colpa DI, Habib MHM, Fraaije MW (2016) Bacterial enzymes involved in lignin degradation. J Biotechnol 236: 110-119.

- Bleichrodt FS, Fischer R, Gerischer UC (2010) The β-ketoadipate pathway of Acinetobacter baylyi undergoes carbon catabolite repression, cross-regulation and vertical regulation, and is affected by Crc. Microbiology 156: 1313-1322.

- Santala S, Efimova E, Kivinen V, Larjo A, Aho T, et al. (2011) Improved triacylglycerol production in Acinetobacter baylyi ADP1 by metabolic engineering. Microb Cell Fact 10: 36.

- Eggeling L, Sahm H (1980) Degradation of conyferyl alcohol and other lignin-related aromatic compounds by Nocardia sp. DSM 1069. Arch Microbiol 126: 141-148.

- Alvarez HM, Steinbüchel A (2002) Triacylglycerols in prokaryotic microorganisms. Appl Microbiol Biot 60: 367-376.

- Arabolaza A, Rodriguez E, Altabe S, Alvarez H, Gramajo H (2008) Multiple pathways for triacylglycerol biosynthesis in Streptomyces coelicolor. Appl Environ Microbiol 74: 2573-2582.

- Davis JR, Sello JK (2010) Regulation of genes in Streptomyces bacteria required for catabolism of lignin-derived aromatic compounds. Appl Microbiol Biotechnol 86: 921-929.

- Kosa M, Ragauskas AJ (2011) Lipids from heterotrophic microbes: Advances in metabolism research. Trends Biotechnol 29: 53-61.

- Kosa M, Ragauskas AJ (2012) Bioconversion of lignin model compounds with oleaginous Rhodococci. Appl Microbiol Biotechnol 93: 891-900.

- Kosa M, Ragauskas AJ (2013) Lignin to lipid bioconversion by oleaginous Rhodococci. Green Chem 15: 2070-2074.

- Wells Jr T, Wei W, Ragauskas A (2015) Bioconversion of lignocellulosic pretreatment effluent via oleaginous Rhodococcus opacus DSM 1069. Biomass and Bioenerg 72: 200-205.

- Rajaka RC, Banerjee R (2015) Enzymatic delignification: an attempt for lignin degradation from lignocellulosic feedstock. RSC Advances 5: 75281-75291.

- Kataeva I, Foston MB, Yang SJ, Pattathil S, Biswal AK, et al. (2013) Carbohydrate and lignin are simultaneously solubilized from unpretreated switchgrass by microbial action at high temperature. Energ Environ Sci 6: 2186-2195.

- Fu C, Mielenz JR, Xiao X, Ge Y, Hamilton CY, et al. (2011) Genetic manipulation of lignin reduces recalcitrance and improves ethanol production from switchgrass. PNAS 108: 3803-3808.

- Hu F, Jung S, Ragauskas A (2012) Pseudo-lignin formation and its impact on enzymatic hydrolysis. Bioresource Technol 117: 7-12.

- Fougere D, Nanda S, Clarke K, Kozinski JA, Li K (2016) Effect of acidic pretreatment on the chemistry and distribution of lignin in aspen wood and wheat straw substrates. Biomass and Bioenerg 91: 56-68.

- Sannigrahi P, Kim DH, Jung S, Ragauskas A (2011) Pseudo-lignin and pretreatment chemistry. Energ Environ Sci 4: 1306-1310.

- Xu C, Ferdosian F (2017) Conversion of lignin into bio-based chemicals and materials, Springer, Berlin, Germany.

- Caballero JA, Font R, Marcilla A (1997) Pyrolysis of Kraft lignin: Yields and correlations. J Anal Appl Pyrol 39: 161-183.

- Ferdous D, Dalai AK, Bej SK, Thring RW (2002) Pyrolysis of lignins: Experimental and kinetics studies. Energ Fuel 16: 1405-1412.

- Mu W, Ben H, Ragauskas A, Deng Y (2013) Lignin pyrolysis components and upgrading—technology review. Bioenerg Res 6: 1183-1204.

- Sharma RK, Wooten JB, Baliga VL, Lin X, Geoffrey CW, et al. (2004) Characterization of chars from pyrolysis of lignin. Fuel 83: 1469-1482.

- Hosoya T, Kawamoto H, Saka S (2009) Role of methoxyl group in char formation from lignin-related compounds. J Anal Appl Pyrol 84: 79-83.

- Chu S, Subrahmanyam AV, Huber GW (2013) The pyrolysis chemistry of a β-O-4 type oligomeric lignin model compound. Green Chem 15: 125-136.

- Jiang G, Nowakowski DJ, Bridgwater AV (2010) Effect of the temperature on the composition of lignin pyrolysis products. Energ Fuel 24: 4470-4475.

- Patwardhan PR, Brown RC, Shanks BH (2011) Understanding the fast pyrolysis of lignin. ChemSusChem 4: 1629-1636.

- Scholze B, Meier D (2001) Characterization of the water insoluble fraction from pyrolysis oil (pyrolytic lignin). Part I. PY-GC/MS, FTIR, and functional groups. J Anal Appl Pyrol 60: 41-54.

- Mohanty P, Nanda S, Pant KK, Naik S, Kozinski JA, et al. (2013) Evaluation of the physiochemical development of biochars obtained from pyrolysis of wheat straw, timothy grass and pinewood: Effects of heating rate. J Anal Appl Pyrol 104: 485-493.

- Nanda S, Mohanty P, Kozinski JA, Dalai AK (2014) Physico-chemical properties of bio-oils from pyrolysis of lignocellulosic biomass with high and slow heating rate. Energ Environ Res 4: 21-32.

- Greenwood PF, van Heemst JDH, Guthrie EA, Hatcher PG (2002) Laser micropyrolysis GC-MS of lignin. J Anal Appl Pyrol 62: 365-373.

- Nanda S, Rana R, Zheng Y, Kozinski JA, Dalai AK (2017) Insights on pathways for hydrogen generation from ethanol. Sustainable Energy and Fuels 1: 1232-1245.